Our

Sustainable Answer

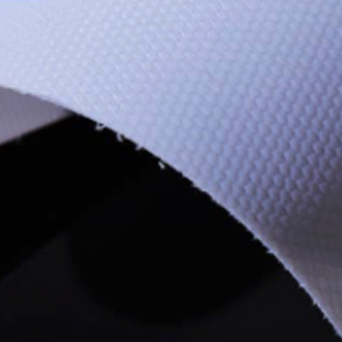

EcoLattice emerges as a much-needed alternative to traditional PU, offering a material solution that not only provides long-lasting comfort but rewrites the script on responsibility. Our EcoLattice foam is not only recyclable but also reduces the need for toxic fire retardants thanks to its structural design and polymer stability. Its lightweight nature lowers shipping emissions and makes it easier to integrate into modular or flat-pack designs, further aligning with low-impact manufacturing and distribution strategies.