From Foam to the Future

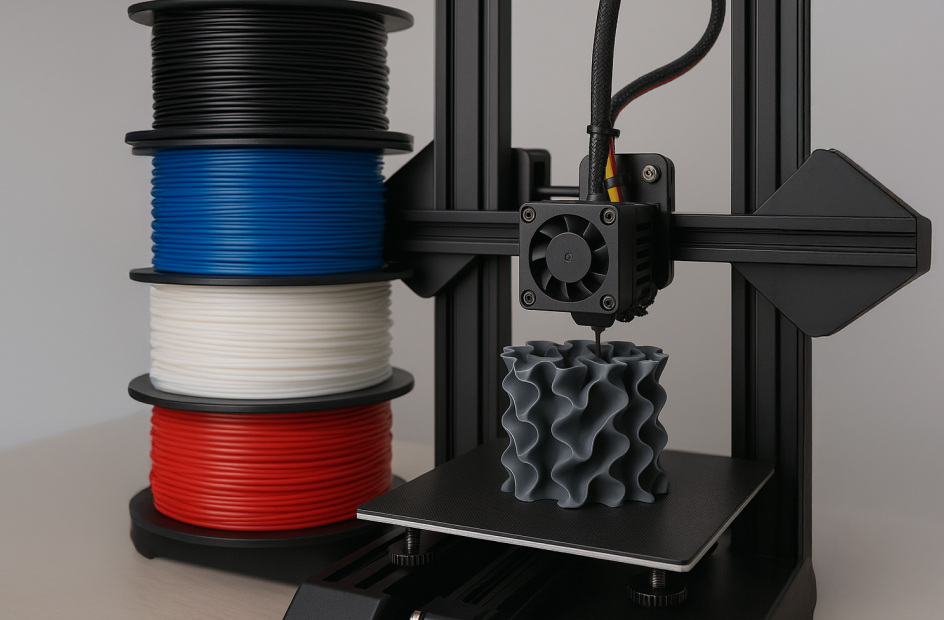

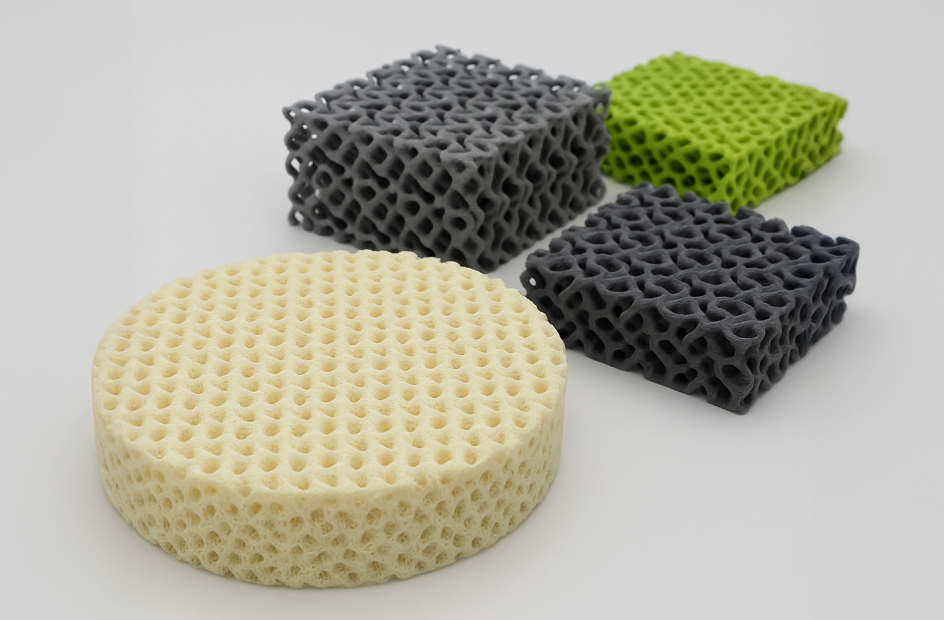

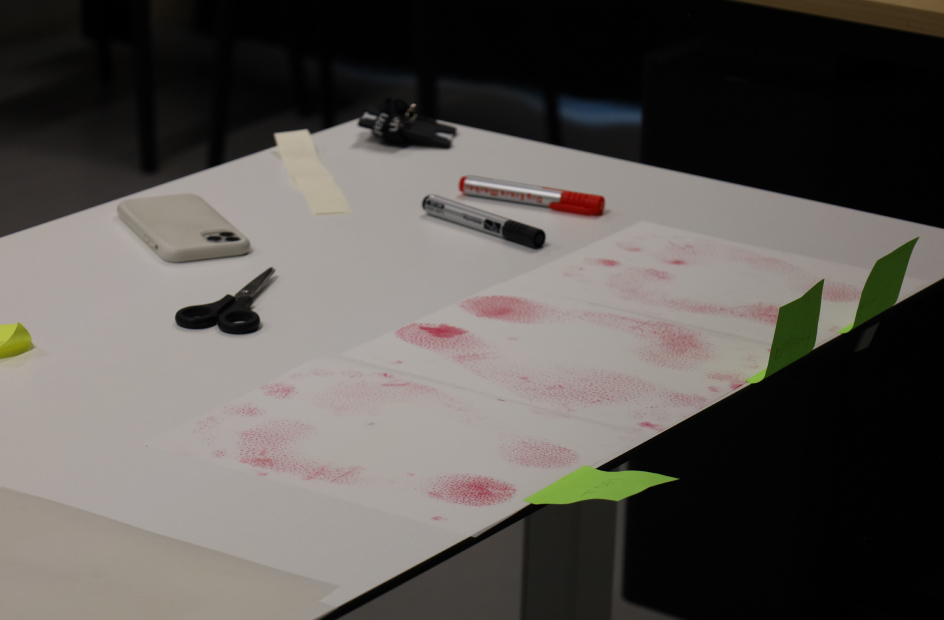

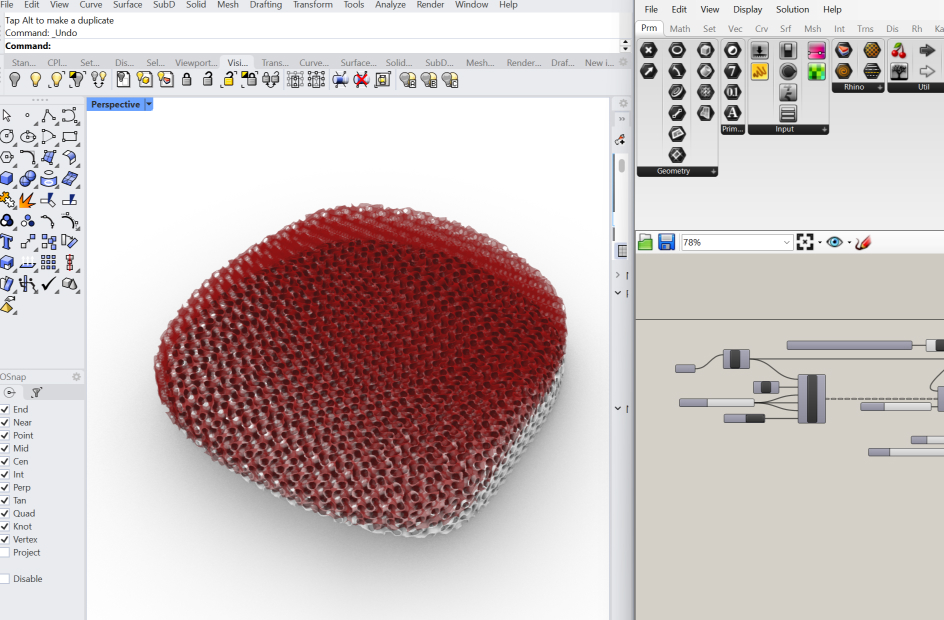

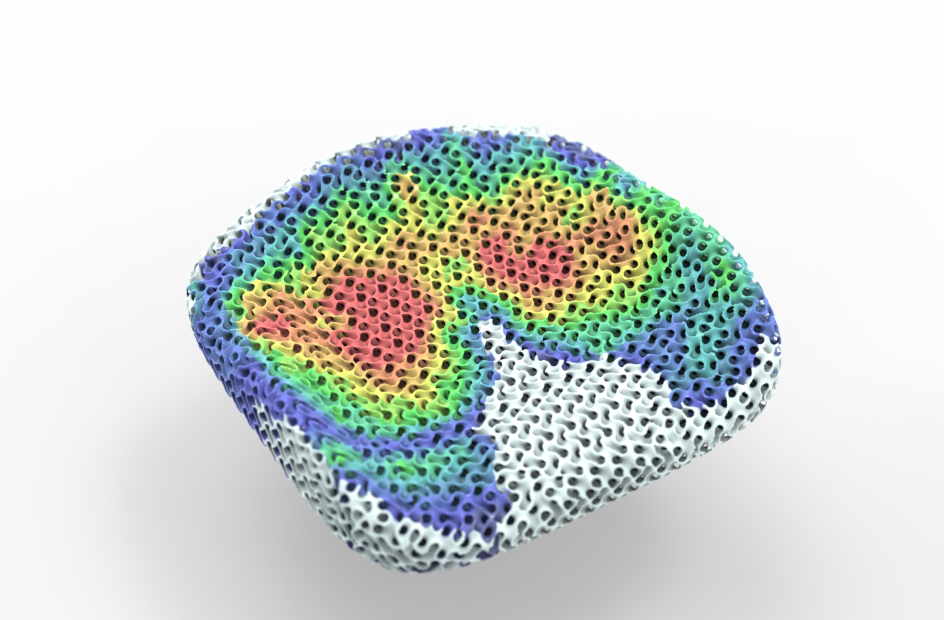

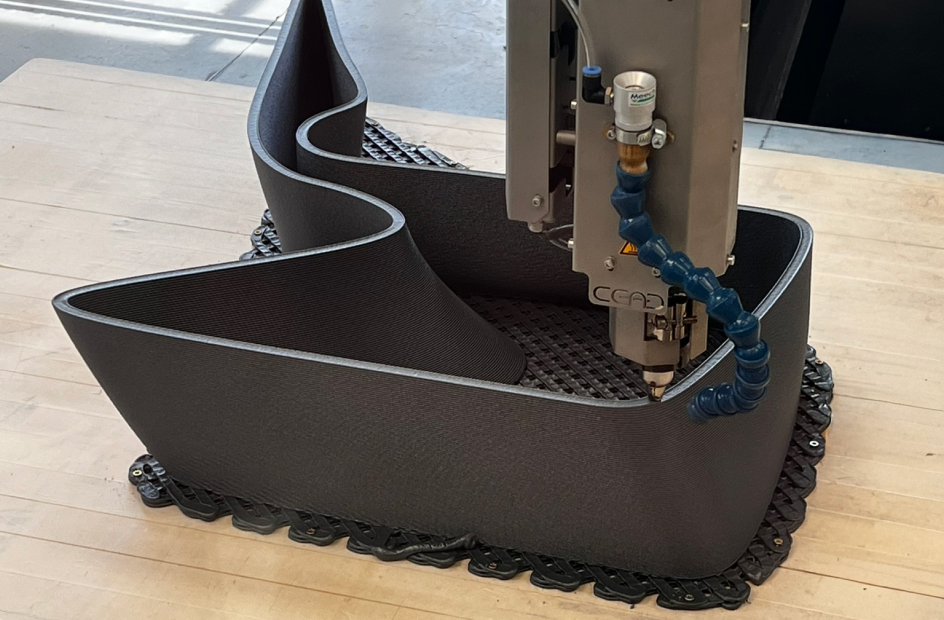

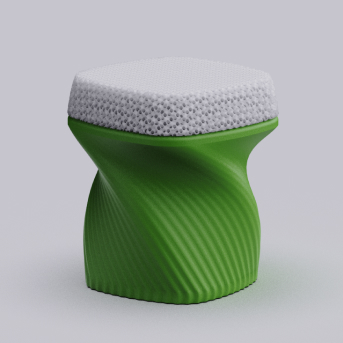

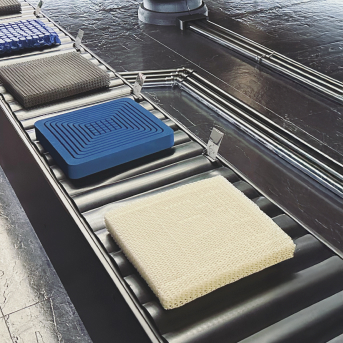

At EcoLattice, we merge circular design, sustainable materials, and digital technology to reimagine foams. We are committed to creating durable, recyclable, and customisable alternatives to polyurethane by reclaiming waste elastomers and transforming them into 3D-printed lattices. We turn discarded plastics into high-performance products while our digital tools ensure precision, personalisation, and zero-waste production.

Contact Us